Hey All.

So I was happy with how my Street Scene roll pan came out... But Now that I'm going to lower the truck, It wont look right seeing that ugly frame under the truck!

The front lower valance, I painted. (Haven't seen many other guys paint it)

So now I need something on the body's side also.

I bought a 10 foot long 6" diameter PVC pipe at Lowes, and cut it into thirds, length wise.

I did this on my Table saw, and I didn't do a very good job keeping the edges straight. Pipe liked to roll, despite how hard i tried marking it, etc etc. I wonder if anyone else could come up with some good ways of cutting PVC pipe lengthwise. The problem is that as your blade goes through the pipe, the Pipe tries to PINCH the blade.

Anyway... with cutting the pipe in thirds, the bottom edge goes to the frame, and the upper edge comes just past 90, and starts angleing back in towards the truck. Perfect !!!

I plan on welding some Studs to the frame, and key holing some holes on the framework of the side skirts (height adjustability). It's 1/4" thick pipe, so I'll be able to counter flush some Rivets on the outer side of the skirts, and fill w/ body filler to make it look flush outside.

For the ends, in the wheel wells, I have some 6" diameter PVC End Caps that I'll plastic weld onto the inner side, and smooth out.

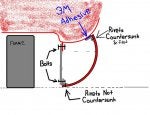

Here's a photoshop of how it will look, and a Paint image of the planned brackets.

Wish me luck, and tell me what you think:

So I was happy with how my Street Scene roll pan came out... But Now that I'm going to lower the truck, It wont look right seeing that ugly frame under the truck!

The front lower valance, I painted. (Haven't seen many other guys paint it)

So now I need something on the body's side also.

I bought a 10 foot long 6" diameter PVC pipe at Lowes, and cut it into thirds, length wise.

I did this on my Table saw, and I didn't do a very good job keeping the edges straight. Pipe liked to roll, despite how hard i tried marking it, etc etc. I wonder if anyone else could come up with some good ways of cutting PVC pipe lengthwise. The problem is that as your blade goes through the pipe, the Pipe tries to PINCH the blade.

Anyway... with cutting the pipe in thirds, the bottom edge goes to the frame, and the upper edge comes just past 90, and starts angleing back in towards the truck. Perfect !!!

I plan on welding some Studs to the frame, and key holing some holes on the framework of the side skirts (height adjustability). It's 1/4" thick pipe, so I'll be able to counter flush some Rivets on the outer side of the skirts, and fill w/ body filler to make it look flush outside.

For the ends, in the wheel wells, I have some 6" diameter PVC End Caps that I'll plastic weld onto the inner side, and smooth out.

Here's a photoshop of how it will look, and a Paint image of the planned brackets.

Wish me luck, and tell me what you think: