So I've had alot of people over the last year txt, msg, and email me about my turbo setup and I always refer them to my build thread, but seeing as most of us have whored it into oblivion (myself included) I thought it would be a good idea to create a quick reference thread to sort of consolidate what has probably been the longest, most painstaking turbo build in history.

Please note that all advice given is from my own experience and the experience of others who have proven their abilities when adding forced induction to these motors. It should also be noted that most of this experience and examples are from the 3.5L and 3.7L 5-cylinder engines and that this thread is simply to act as a guide down the path to enlightenment. We will always do the best we can to update and fact check all given information, but please before you go gung ho turboing your truck, consult with those of us who have experience and also with your local tuners and speed shops who will undoubtedly be helping you on this journey

So without more giberish from me, here we go:

First of all, the base of my kit is an STS Universal Single Turbo Kit and also bought a pipe kit, which alter turned out to be basically unneccesary. This kit, with a PCV valve kit costs around $2300 shipped and includes most of what you need in one convenient package, as well as STS's full customer support which is awesome btw, and a custom spec'd turbo charger so you won't have to guess the proper spec'd turbo charger for your application. This is especially nice for beginners like myself who are still learning.

Second, my intercooler is a TRV1259 from Treadstone Performance and is capable of supporting 500hp or airflow. It will create a 1.5psi drop in pressure, but will chill the incoming charge air which is necessary for California summers and also because of how the charge piping must be routed on these trucks. $260 + Shipping

To do the fuel system, I ordered both 60 and 80# Seimens EV1 style injectors and pigtail adapters from a former board vendor and project supporter. They are no longer a part of the build for reasons I'd rather not discuss, but you can find these same parts from limequat who is a knowledgeable builder and available here on the board. These parts run about $300 shipped for 5 injectors and harnesses. I ended up using the 60# units, but have the 80# units should I switch to E85 or bump the power past the 500hp mark. The 60# units are more than enough to handle 450+hp at the crank and on my truck during road testing at WOT only reached 50% of their duty cycle. Where we recently ran into problems was in keeping the fuel pressure high enough for big power runs. Some people have had great luck with their stock pumps, running more than 500hp out of them, but my own ran out of huff just above 400hp at the crank. When shooting for big power, it is recommended that you switch to a larger fuel pump. How large is entirely up to you, but a proven solution is the Walbro 255lph pump. If you are running E85 (ethanol) then a pair of these may be required to supply your fuel needs for larger power runs.

Limequat is also now supplying turbo manifolds for the I5!!! http://www.lime-swap.com/manifolds

Along with these pieces, I also got a MAF adapter from Sinisty Kustomz and left the truck with Jonny Vico in Fresno for the fabrication.

Here are some results for you:

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

Piping after paint:

![Image]()

![Image]()

Now since these pictures were taken, we have redone the exhaust side of the build and added support brackets and hangers to the turbo and exhaust system and are currently going to rework the charge piping to make it a tad more efficient and easier to work with.

On to tuning!

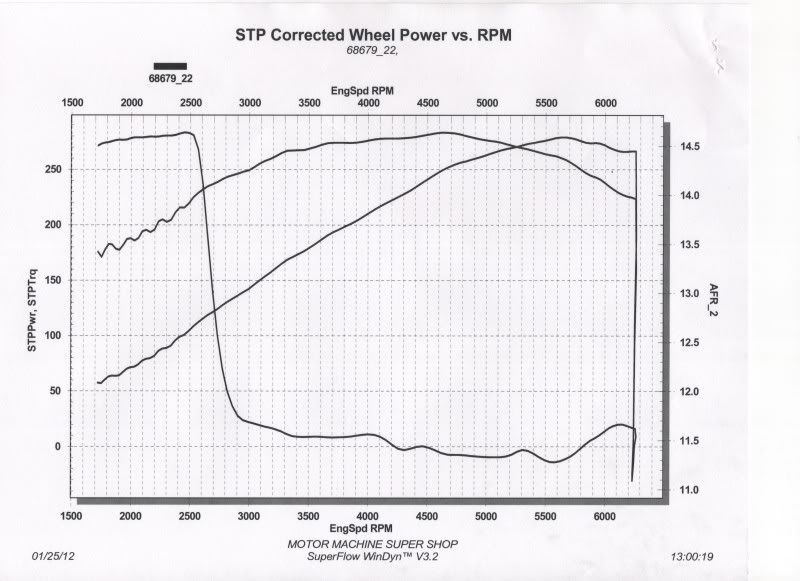

This is where we ran into a MOUNTAIN of issues, mostly due to the first tuner being a complete moron and a dirtbag. That being said, my new tuner, and sponsor, Motor Machine Super Shop have been nothing short of the most awesome group I have ever worked with. These guys pulled some LONG days cleaning up the mess that I had brought them and with a little help from Cory (05_quick4door) they were able to tune the truck and get it driveable. They made over 30 pulls on the dyno and some time on the street, logging EVERYTHING and seperating each tune file for each pull. Eventually the truck made 280rwhp on just 5.5psi on a super safe tune for 91oc.

![Image]()

This tune file is available to anyone who wants it and I will gladly have it emailed to you should you request it.

Now, where we ran into problems and why we blew up: We are 90% sure that our detonation was due to a load of bad gas, combined with running the truck very hard repeatedly (back to back to back 1/4mi runs) resulted in disaster. Other than when we truly and honestly beat the thing into submission, it had 0 problems and we have the logs to prove it. IAT's are low, timing and fuel is conservative, etc. This tune file would be a great place to start and would only require minor tweaks (provided you are running the 60# injectors like I am)

Running a piggy back system for the fuel and spark has been discussed at length, but ultimately it is unnecessary. While the stock ECM does not have the best resolution for adjusting the fuel trims, it can still do the job quite well for 99% of us. The overwhelming consensus is that HPtuners is the only program for the job and with the help of a competent tuner, it is actually not very hard to tune.

Impressions: Everyone wants to assume that because the turbo is so far away from tha manifold that there will be massive lag, and I'll tell you right now, there is less lag in this system than a conventional turbo system. I was making boost before 3krpm. You could hear the turbo doing it's thing by 2100rpm and son of a bitch did it pull. The difference between this and the stock motor is a total non comparison. The engine LOVED the small amount of boost we were giving it. If you can keep control of your desire for more power, you can easily have a very reliable 300+hp driver. Once you start creeping into the 10psi range, you need to be very careful. I strongly suggest meth injection once you get past the 8psi mark due to the potential for disaster like what happened to myself and Cory. It can also help on those hot summer days when you wanna go for a spirited drive

I think that's it for now. If I remember anything else, I'll post up and as always, I am available with any information I can get for you about my build. For those following along, I'm currently rebuilding the motor with forged internals and should have a full writeup for that process, along with part numbers, work orders, etc so should you feel the need to overbuild a motor or make 700hp, I've got your back :salute:

Turbo Sizing explained:

Turbo sizing is mainly dependent on your power goal. The motor's compression ratio and the fuel being used determines roughly how much boost you'll need to run in order to reach your power goal (specific to turbochargers). The rules are different for roots style blowers.

Knowing how to read a compressor map is a must. I'll try to get into that when I have more time.

If I want to make 600 hp at the flywheel, I'd first look at compressors rated for 700 hp at the flywheel because you don't want to overwork the turbo to reach your goal. Then out of the list of turbos that fall within this catagory, I would read their compressor maps to determine which one will meet your needs at the predetermined boost pressure. (boost pressure is never set in stone with a fully custom turbo setup because it can vary +/-5psi).

Running a small turbo just to get it to make boost at a low rpm like a roots blower IMO is only okay for the guys who want better gas mileage and torque for towing but you run into issues with surge in higher engine rpm's due to fact that the smaller compressor cannot flow enough air to keep the intake manifold pressurized (boost drop).

I suggest for those spoiled kids who want to mimic v8-like power and torque response to do a v8 swap because that's the only way to get it because if it's one thing that they do like, there's always something else that they don't like. They'll always be unhappy because their energy is always focused on the negative.

Boost pressure is not directly associated with how much hp you will make. I can slap on an 88mm turbo and make 500 hp to the wheels on 8 psi once it's spooled. It all depends on the compressor map and how much air it can flow. So add that to the list of no noes. Pay attention to the volume measurements, ie lbs/min vs lbs/hr

Cory (05_quick4door) recommends a 60mm turbo for "normal daily use" meaning your power goals are modest and attainable without getting crazy with other supporting mods. The next step up is a 67mm for a bit more power and after that somewhere in the 70+mm range. These are on a 5cyl. On the 4cyl, step is down one notch for each given power goal; 55mm, 60mm, 67mm. (This is only to simplify things a bit. These are not 100% accurate turbo sizes, but simply to give you a better idea of what to search for.)

Here's a couple good easy to understand links for turbo sizing:

How to Pick a Correct Turbocharger Size | eHow.com

Turbo Calculator | HorsepowerCalculators.net

Garret Turbochargers has a handy little calculator on their website that's fun to play with and will recommend a list of turbos for you even

Garrett Boost Adviser - Online | Turbobygarrett

Please note that all advice given is from my own experience and the experience of others who have proven their abilities when adding forced induction to these motors. It should also be noted that most of this experience and examples are from the 3.5L and 3.7L 5-cylinder engines and that this thread is simply to act as a guide down the path to enlightenment. We will always do the best we can to update and fact check all given information, but please before you go gung ho turboing your truck, consult with those of us who have experience and also with your local tuners and speed shops who will undoubtedly be helping you on this journey

So without more giberish from me, here we go:

First of all, the base of my kit is an STS Universal Single Turbo Kit and also bought a pipe kit, which alter turned out to be basically unneccesary. This kit, with a PCV valve kit costs around $2300 shipped and includes most of what you need in one convenient package, as well as STS's full customer support which is awesome btw, and a custom spec'd turbo charger so you won't have to guess the proper spec'd turbo charger for your application. This is especially nice for beginners like myself who are still learning.

Second, my intercooler is a TRV1259 from Treadstone Performance and is capable of supporting 500hp or airflow. It will create a 1.5psi drop in pressure, but will chill the incoming charge air which is necessary for California summers and also because of how the charge piping must be routed on these trucks. $260 + Shipping

To do the fuel system, I ordered both 60 and 80# Seimens EV1 style injectors and pigtail adapters from a former board vendor and project supporter. They are no longer a part of the build for reasons I'd rather not discuss, but you can find these same parts from limequat who is a knowledgeable builder and available here on the board. These parts run about $300 shipped for 5 injectors and harnesses. I ended up using the 60# units, but have the 80# units should I switch to E85 or bump the power past the 500hp mark. The 60# units are more than enough to handle 450+hp at the crank and on my truck during road testing at WOT only reached 50% of their duty cycle. Where we recently ran into problems was in keeping the fuel pressure high enough for big power runs. Some people have had great luck with their stock pumps, running more than 500hp out of them, but my own ran out of huff just above 400hp at the crank. When shooting for big power, it is recommended that you switch to a larger fuel pump. How large is entirely up to you, but a proven solution is the Walbro 255lph pump. If you are running E85 (ethanol) then a pair of these may be required to supply your fuel needs for larger power runs.

Limequat is also now supplying turbo manifolds for the I5!!! http://www.lime-swap.com/manifolds

Along with these pieces, I also got a MAF adapter from Sinisty Kustomz and left the truck with Jonny Vico in Fresno for the fabrication.

Here are some results for you:

Piping after paint:

Now since these pictures were taken, we have redone the exhaust side of the build and added support brackets and hangers to the turbo and exhaust system and are currently going to rework the charge piping to make it a tad more efficient and easier to work with.

On to tuning!

This is where we ran into a MOUNTAIN of issues, mostly due to the first tuner being a complete moron and a dirtbag. That being said, my new tuner, and sponsor, Motor Machine Super Shop have been nothing short of the most awesome group I have ever worked with. These guys pulled some LONG days cleaning up the mess that I had brought them and with a little help from Cory (05_quick4door) they were able to tune the truck and get it driveable. They made over 30 pulls on the dyno and some time on the street, logging EVERYTHING and seperating each tune file for each pull. Eventually the truck made 280rwhp on just 5.5psi on a super safe tune for 91oc.

This tune file is available to anyone who wants it and I will gladly have it emailed to you should you request it.

Now, where we ran into problems and why we blew up: We are 90% sure that our detonation was due to a load of bad gas, combined with running the truck very hard repeatedly (back to back to back 1/4mi runs) resulted in disaster. Other than when we truly and honestly beat the thing into submission, it had 0 problems and we have the logs to prove it. IAT's are low, timing and fuel is conservative, etc. This tune file would be a great place to start and would only require minor tweaks (provided you are running the 60# injectors like I am)

Running a piggy back system for the fuel and spark has been discussed at length, but ultimately it is unnecessary. While the stock ECM does not have the best resolution for adjusting the fuel trims, it can still do the job quite well for 99% of us. The overwhelming consensus is that HPtuners is the only program for the job and with the help of a competent tuner, it is actually not very hard to tune.

Impressions: Everyone wants to assume that because the turbo is so far away from tha manifold that there will be massive lag, and I'll tell you right now, there is less lag in this system than a conventional turbo system. I was making boost before 3krpm. You could hear the turbo doing it's thing by 2100rpm and son of a bitch did it pull. The difference between this and the stock motor is a total non comparison. The engine LOVED the small amount of boost we were giving it. If you can keep control of your desire for more power, you can easily have a very reliable 300+hp driver. Once you start creeping into the 10psi range, you need to be very careful. I strongly suggest meth injection once you get past the 8psi mark due to the potential for disaster like what happened to myself and Cory. It can also help on those hot summer days when you wanna go for a spirited drive

I think that's it for now. If I remember anything else, I'll post up and as always, I am available with any information I can get for you about my build. For those following along, I'm currently rebuilding the motor with forged internals and should have a full writeup for that process, along with part numbers, work orders, etc so should you feel the need to overbuild a motor or make 700hp, I've got your back :salute:

Turbo Sizing explained:

Turbo sizing is mainly dependent on your power goal. The motor's compression ratio and the fuel being used determines roughly how much boost you'll need to run in order to reach your power goal (specific to turbochargers). The rules are different for roots style blowers.

Knowing how to read a compressor map is a must. I'll try to get into that when I have more time.

If I want to make 600 hp at the flywheel, I'd first look at compressors rated for 700 hp at the flywheel because you don't want to overwork the turbo to reach your goal. Then out of the list of turbos that fall within this catagory, I would read their compressor maps to determine which one will meet your needs at the predetermined boost pressure. (boost pressure is never set in stone with a fully custom turbo setup because it can vary +/-5psi).

Running a small turbo just to get it to make boost at a low rpm like a roots blower IMO is only okay for the guys who want better gas mileage and torque for towing but you run into issues with surge in higher engine rpm's due to fact that the smaller compressor cannot flow enough air to keep the intake manifold pressurized (boost drop).

I suggest for those spoiled kids who want to mimic v8-like power and torque response to do a v8 swap because that's the only way to get it because if it's one thing that they do like, there's always something else that they don't like. They'll always be unhappy because their energy is always focused on the negative.

Boost pressure is not directly associated with how much hp you will make. I can slap on an 88mm turbo and make 500 hp to the wheels on 8 psi once it's spooled. It all depends on the compressor map and how much air it can flow. So add that to the list of no noes. Pay attention to the volume measurements, ie lbs/min vs lbs/hr

Cory (05_quick4door) recommends a 60mm turbo for "normal daily use" meaning your power goals are modest and attainable without getting crazy with other supporting mods. The next step up is a 67mm for a bit more power and after that somewhere in the 70+mm range. These are on a 5cyl. On the 4cyl, step is down one notch for each given power goal; 55mm, 60mm, 67mm. (This is only to simplify things a bit. These are not 100% accurate turbo sizes, but simply to give you a better idea of what to search for.)

Here's a couple good easy to understand links for turbo sizing:

How to Pick a Correct Turbocharger Size | eHow.com

Turbo Calculator | HorsepowerCalculators.net

Garret Turbochargers has a handy little calculator on their website that's fun to play with and will recommend a list of turbos for you even

Garrett Boost Adviser - Online | Turbobygarrett